Connecting the Shop Floor to the Office

THE SOFTWARE used to connect machine tools to the programmer is called DIRECT NUMERICAL CONTROL or DNC for short.

Like the machines they interface with, DNC packages have evolved tremendously in the past ten years.

DNC software can range from simple “One Machine at a Time” communication to sophisticated Document Tracking Packages designed to fulfill the strictest ISO requirements.

Some of the more common features of a DNC software package are:

- Remote Call-down, which allows operators to request part programs directly from the CNC.

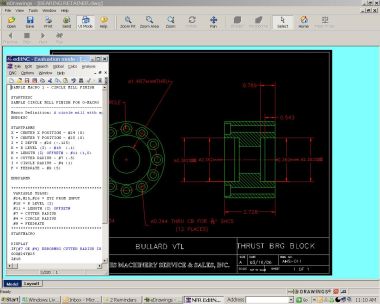

- Program Editors, with built-in Trig. Functions.

- Program Compare, to allow a quick way of finding program differences.

- Back Plotting, to view the tool path before cutting.

- Pre-defined File Management, so that uploaded files are kept separate from downloaded ones.

Because DNC software features affect cost, and every shop’s need are unique; AHS provides a wide range of software products. This allows us to provide you with a “best fit” package.

Finally there’s SHOP FLOOR MONITORING. Using special Hardware / Software you can collect and monitor the status of machines and work throughout your shop in real time. The more you know about what’s happening on your shop floor, the smoother and more efficient your operation can become.

- Production Control can spot bottlenecks.

- The Maintenance dept. can monitor cycle times to schedule maintenance, or critical items like bearing temperatures to prevent catastrophic failures.

- Purchasing can better schedule material deliveries “just-in-time”….